Precision machining plays a critical role in manufacturing across multiple industries. Whether it’s aerospace components, medical device parts, or intricate automotive components, businesses in the UK rely on high-quality precision machining companies to meet strict tolerances and demanding production standards.

In London, a hub for both industrial development and high-tech innovation, finding the right machining partner can have a significant impact on quality, speed, and long-term business success.

This guide outlines what to look for in a machining company, the most common challenges businesses face, and highlights ten of the top-rated precision machining companies in London based on customer satisfaction and performance.

Why is Choosing the Right Precision Machining Company in London So Important?

Precision machining is all about accuracy. The right company ensures that each part is manufactured to exact specifications, reducing the likelihood of failure in critical systems.

In sectors like aerospace, medical, and automotive manufacturing, even the slightest deviation can result in serious operational or safety consequences. That’s why working with a reputable precision machining partner isn’t just a cost-saving decision. it’s a risk management strategy.

Beyond accuracy, reputable firms offer the flexibility and scalability needed to support both prototype development and full-scale production. The right company will align with a client’s technical needs, material requirements, and production deadlines, ultimately enhancing the efficiency and reliability of the supply chain.

What Should You Look for in a London-based Precision Machining Company?

Selecting the right partner requires careful evaluation of several core attributes. Certification is often the first indicator of reliability. Companies that adhere to standards such as ISO 9001, AS9100 for aerospace, or ISO 13485 for medical devices demonstrate a commitment to quality and compliance.

Technology is another important factor. Modern facilities use CNC machines, 5-axis machining centres, and computer-aided manufacturing tools to produce complex geometries with high precision. These machines reduce the margin of error and ensure repeatability across production runs.

In addition to equipment and standards, customer service also plays a role. A firm that offers open communication, technical consultation, and responsive support adds long-term value to the client relationship. The ability to handle a range of materials like stainless steel, titanium, or specialised polymers also indicates versatility, which is particularly useful when projects evolve over time.

What Services Do Precision Machining Companies Typically Offer in London?

Precision machining companies in London typically offer a comprehensive range of services to cater to diverse industrial demands. The most common service is CNC machining, which includes both milling and turning. These processes are essential for shaping raw materials into high-accuracy components.

Wire EDM and surface grinding are often available for intricate or hard-to-machine parts. Some companies provide design consultation, where engineers help refine the part design before production. Rapid prototyping is also a popular service, especially among startups and R&D teams aiming to test new products quickly and cost-effectively.

Other value-added services might include material sourcing, heat treatment, and surface finishing such as anodising or polishing. These services allow clients to receive fully finished components ready for assembly, reducing the need for external processing.

Who Are the Top 10 Precision Machining Companies in London?

1. HEC Precision – “Performance Engineering at its Finest”

HEC Precision is a recognised leader in high-precision CNC machining, operating from its London base with a commitment to innovation and continuous investment in technology. Serving aerospace, defence, motorsport, and medical sectors, their engineers work to exacting standards.

With extensive CAD/CAM integration and high-speed CNC equipment, HEC Precision manages the full journey from material sourcing to finished component, delivering robust solutions for complex manufacturing challenges. Their strong emphasis on R&D collaboration has made them a preferred supplier for companies requiring technical insight and long-term development support.

Technical Expertise

Comprehensive 3-, 4-, and 5-axis machining with complex programming capabilities.

Suited To

Companies seeking end-to-end precision solutions with engineering input.

Pricing: Quotation-based, reflecting part complexity and batch volume.

- Website: www.hec-precision.co.uk

- Phone: +44 (0)20 85745958

- Address: Unit 5, Cranleigh Gardens Industrial Estate, Southall, Middlesex, UB1 2BZ.

- Email: enquiries@hec-precision.co.uk

Review: ★★★★★

“Great team, great products. Delivered on time with perfect tolerances every time.” – Engineering Director

2. Banda Precision Engineering – “Reliable CNC Machining Across the Capital”

Operating in the heart of London, Banda Precision Engineering provides advanced CNC machining services tailored to small and medium production runs. The company boasts modern CNC milling and turning equipment capable of handling both common and exotic materials.

Known for its friendly service and technical know-how, Banda works with a broad spectrum of industries, including architectural, defence, and automation sectors. Their London location enables fast response times and flexibility for urgent jobs.

Production Focus

Precision CNC machining for medium-complexity industrial components.

Tailored To

Clients needing short-run, repeatable machining with close collaboration.

Pricing: Competitive, project-specific based on design files.

- Website: www.bandaprecisionengineering.co.uk

- Phone: 01772 330321

- Address: Unit 249 Dawson Place, Walton Summit, Bamber Bridge, Preston, Lancashire, PR5 8AL

- Email: info@bandaprecisionengineering.co.uk

Review: ★★★★☆

“Always responsive and committed to quality. A reliable partner for our custom enclosures.” – Procurement Manager

3. MetalTech Precision – “Precision in Every Cut”

With over 30 years of engineering experience, MetalTech Precision has become a trusted name in CNC milling and turning in London. The company is ISO 9001 certified and specialises in high-volume runs of small to medium-sized components.

From raw material sourcing to multi-axis machining and inspection, MetalTech offers full-service manufacturing under one roof. Their ability to deliver repeatable accuracy has made them a preferred supplier for UK OEMs in the defence, oil and gas, and marine sectors.

Engineering Strength

ISO-certified, volume-based CNC machining with full project management.

Best Suited For

Industries requiring repeatable, certified manufacturing standards.

Pricing: Scalable with volume; formal quotes issued on drawing submission.

- Website: www.metal-tech.com

- Phone: 01460 221737

- Address: Yonder Hill, Chard Junction, Somerset, TA20 4QR

- Email: sales@expromet.com

Review: ★★★★★

“They’ve never let us down our preferred supplier for high-accuracy parts.” – Supply Chain Manager

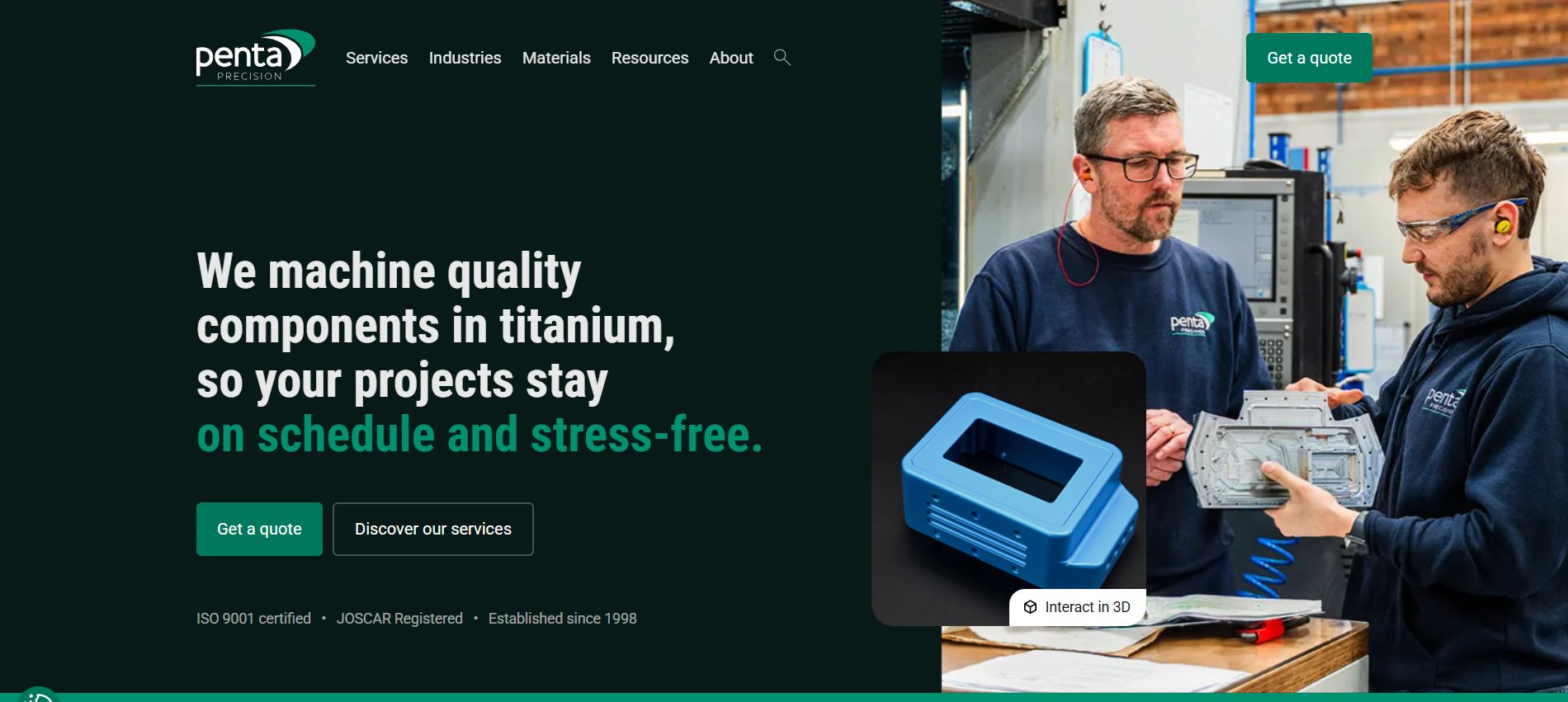

4. Penta Precision – “Engineering Trust Through Precision”

Although based in Portsmouth, Penta Precision services many clients in London and is often chosen for its high-quality CNC machining for medical, defence, and electronics applications.

The company stands out with its transparent quoting system, dedicated customer support, and highly documented quality control processes. Penta combines traditional engineering values with the latest CNC milling and turning technologies to meet critical specifications for tight tolerance parts.

Process Precision

Tight tolerance CNC machining with full traceability and material certification.

Great For

Design teams and QA-driven businesses demanding reliability and documentation.

Pricing: Quotation-based; transparent and detailed quoting provided.

- Website: www.pentaprecision.co.uk

- Phone: 023 9266 8334

- Address: Unit 9 Murrills Estate, Portchester, PO16 9RD

- Email: sales@pentaprecision.co.uk

Review: ★★★★★

“Every quote and part comes with confidence. Their standards are second to none.” – Head of Product Design

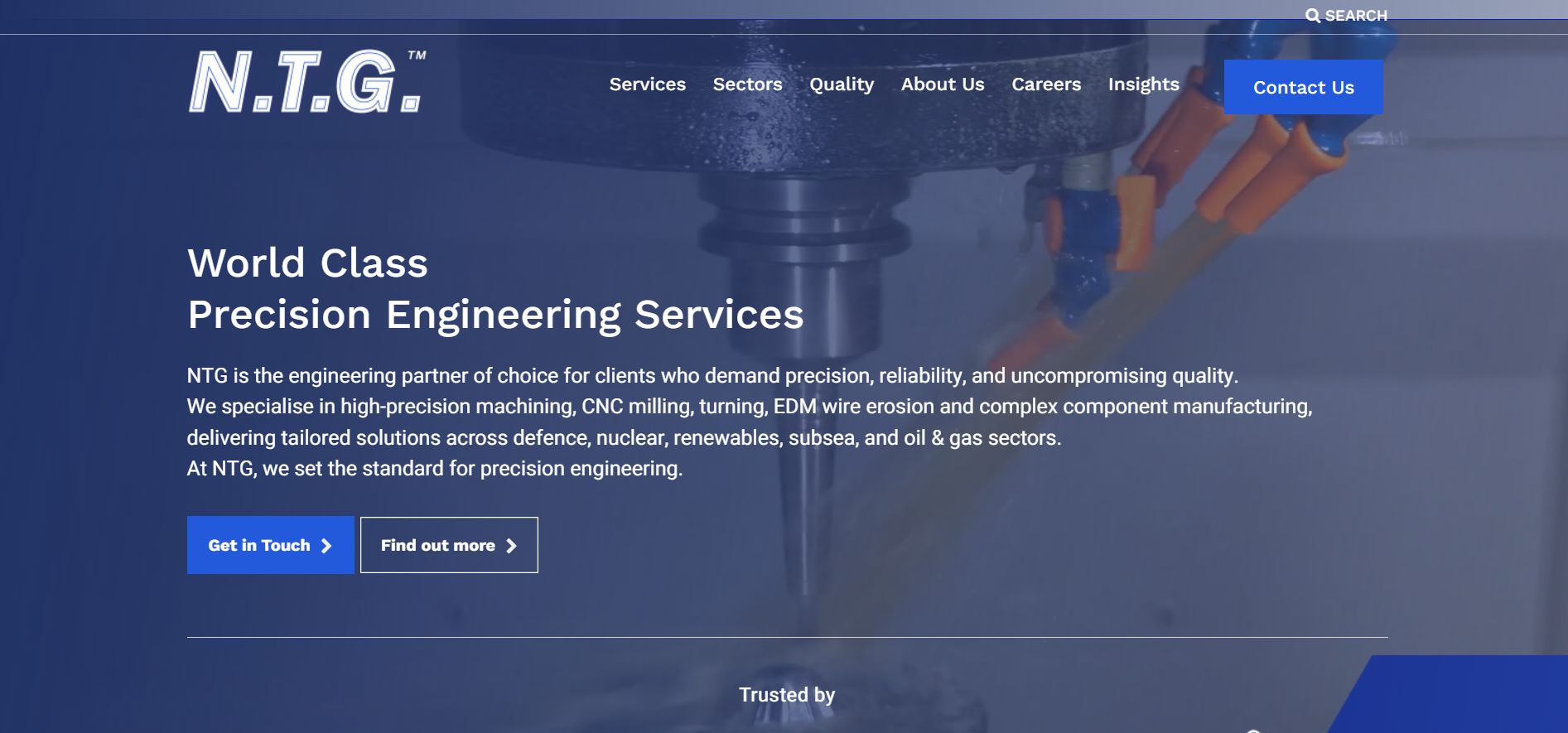

5. NTG Precision Engineers – “High-Spec Machining for Demanding Industries”

NTG is a high-precision machining company supporting clients across London and the UK. With cutting-edge 5-axis and multi-axis CNC machines, they specialise in components for subsea, nuclear, and aerospace industries.

Their high-value machining is backed by a fully traceable QA system and continuous investment in technology. The company also boasts a strong workforce of skilled engineers, enabling them to meet complex technical requirements for critical parts.

Machining Mastery

High-tolerance multi-axis machining for advanced sectors.

Most Useful For

Projects involving mission-critical components in regulated industries.

Pricing: Premium; reflects project complexity and industry compliance.

- Website: www.ntg-ltd.co.uk

- Phone: +44 (0)191 482 2455

- Address: 8th Avenue West, Eighth Ave, Gateshead NE11 0EB, UK

- Email: sales@ntg-ltd.co.uk

Review: ★★★★★

“Delivered aerospace-grade parts with full documentation and zero deviations.” – QA Lead, Aerospace

6. Lloyds Beal – “Versatility in Modern Machining”

Lloyds Beal is a London-based precision machining company offering CNC milling, turning, and surface grinding. Their expertise extends across industries, and their strength lies in managing varied batch sizes from one-offs to medium-scale production.

They are known for prompt turnaround, consistent part quality, and a flexible approach. Their ability to deliver fast, accurate results on both simple and complex parts has made them a valued partner for mechanical contractors and manufacturers.

Versatile Capability

CNC machining with added flexibility for prototype to production.

Recommended For

Businesses needing a fast, responsive partner with diverse machining tools.

Pricing: Market-aligned; quotes based on turnaround and complexity.

- Website: www.lloydsbeal.co.uk

- Phone: 029 2088 4443

- Address: Unit 17, Sir Alfred Owen Way, Pontygwindy Industrial Estate, Caerphilly, CF83 3HU

- Email: sales@lloydsbeal.co.uk

Review: ★★★★☆

“Reliable, responsive, and always keen to help. Excellent service time after time.” – Site Manager

7. JK Engineering – “Built on Precision, Powered by Passion”

With a rich history in subcontract engineering, JK Engineering offers tailored machining services for a broad array of sectors including scientific instruments, aerospace, and energy.

The company excels at short-run prototyping, batch production, and technical collaboration. Operating from a well-equipped facility, they integrate 3D CAD/CAM technology and multi-axis machines to create accurate, repeatable parts with short lead times.

Precision Skillset

Custom-engineered CNC solutions for development and production.

Best For

Engineering teams needing short-run, quality-controlled part manufacturing.

Pricing: Flexible, based on client brief and material choice.

- Website: www.jkeng.co.uk

- Phone: 01923 291555

- Address: Unit 2 Leewood Farm, Harthall Lane, Kings Langley, Watford, Herts WD4 8JJ

- Email: sales@jkeng.co.uk

Review: ★★★★★

“Exceptional attention to detail and top-notch customer service from start to finish.” – R&D Engineer

8. Geomiq – “Data-Driven Manufacturing on Demand”

Geomiq is not a traditional machine shop but a digital manufacturing platform offering CNC machining in London through a vetted supplier network. Users upload CAD files, receive instant quotes, and access a vast supply chain capable of prototyping and production.

The platform uses AI and automated DFM checks to ensure manufacturability and transparency. This modern approach is ideal for engineers needing speed, scalability, and instant pricing for custom parts.

Digital Advantage

AI-powered quoting and supply chain management for on-demand CNC parts.

Ideal For

Design teams needing prototypes and production at the click of a button.

Pricing: Instant quoting with price scaling by quantity and complexity.

- Website: www.geomiq.com

- Phone: +44 20 3962 9020

- Address: 45 Vyner Street, London, E2 9DQ, United Kingdom

- Email: support@geomiq.com

Review: ★★★★☆

“Saves us hours on quoting and sourcing. High-quality parts with real-time tracking.” – Product Manager

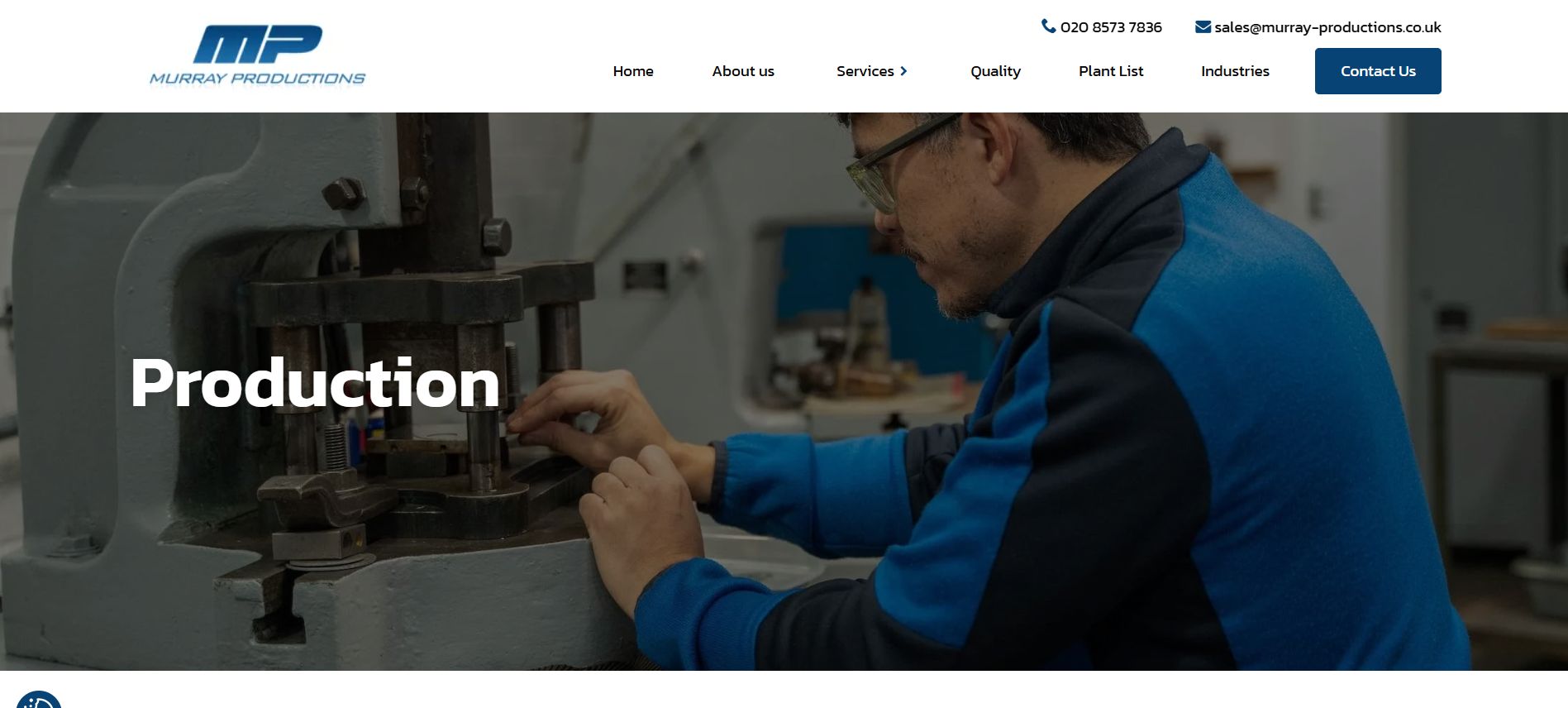

9. Murray Productions – “Machining with an Artistic Edge”

Based in South London, Murray Productions combines creative manufacturing with technical machining. Known for working with artists, architectural firms, and industrial clients, they specialise in prototyping, fabrication, and custom CNC work.

Their unique positioning at the intersection of industrial and creative sectors makes them a go-to for high-quality one-off or low-volume jobs where both appearance and function matter.

Creative Machining

CNC and fabrication tailored to artistic, bespoke, and architectural work.

Perfect For

Designers, makers, and engineers needing parts that also look great.

Pricing: Custom project quotes; higher for creative prototyping.

- Website: www.murray-productions.co.uk

- Phone: 020 8573 7836

- Address: Unit B, Horton Close, West Drayton, London, UB7 8EB

- Email: sales@murray-productions.co.uk

Review: ★★★★☆

“They brought our sculpture to life in aluminium beautiful craftsmanship!” – Artist and Designer

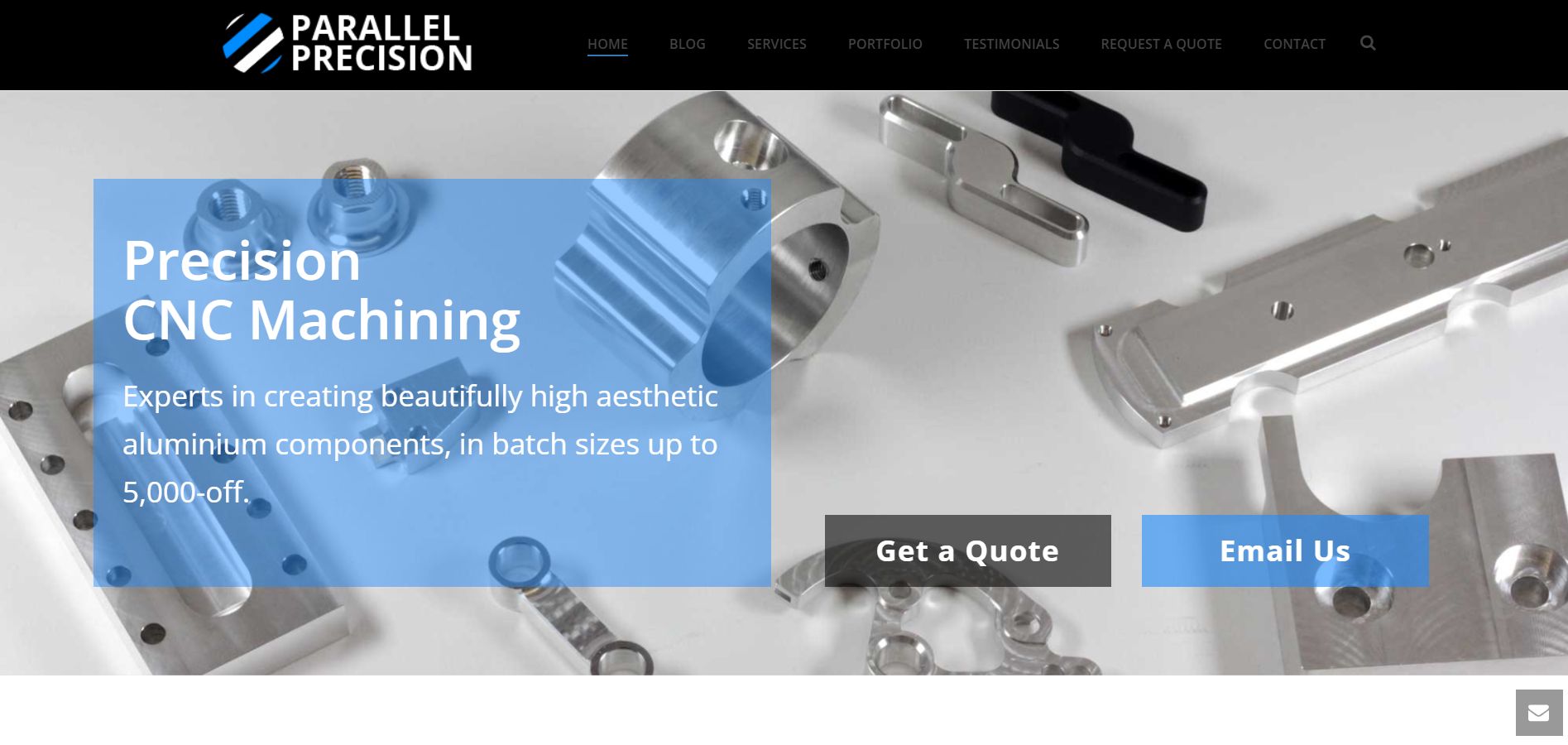

10. Parallel Precision – “CNC Perfection from Start to Finish”

Parallel Precision is known for its detailed approach to part manufacture and assembly. Their Gloucester-based facility regularly services London businesses needing reliable CNC milling, turning, and component finishing.

Their specialty lies in repeatable precision, and they support customers from prototyping to ongoing production. Parallel’s hands-on customer support, CAD expertise, and ISO 9001 accreditation make them a favourite for engineers who value detailed communication and quality assurance.

Machining Integrity

From concept to inspection, CNC parts delivered with reliability.

Well-Suited To

Engineers and manufacturers requiring ongoing batch production with QC.

Pricing: Mid-to-high, reflecting traceability and support.

- Website: www.parallelprecision.co.uk

- Phone: 01452 234733

- Address: Gloucester (servicing London)

- Email: info@parallelprecision.co.uk

Review: ★★★★★

“They consistently hit tight tolerances and deliver on schedule. Great supplier.” – Operations Manager

How Do London Machining Companies Maintain High Levels of Accuracy and Quality?

Quality is maintained through a combination of advanced technology, stringent inspection protocols, and experienced staff. Most precision machining companies in London invest heavily in automated CNC systems that can perform multiple machining operations in a single setup. This reduces human error and increases consistency, particularly for complex parts.

In-house quality assurance teams use tools such as coordinate measuring machines (CMMs), laser scanners, and digital callipers to verify dimensions against CAD specifications. Many companies also implement statistical process control (SPC) and real-time data monitoring to detect and correct variations before they become issues.

An often-overlooked factor is the skill level of machinists and engineers. Skilled personnel with years of experience in multiple industries are better equipped to foresee problems, suggest design improvements, and maintain high production standards.

What Industries Rely on Precision Machining Services in London?

Precision machining supports a wide range of industries, and in London, this includes some of the UK’s most critical sectors. The aerospace and defence industries require components that meet extremely tight tolerances and are often subject to extensive regulatory scrutiny. Companies that serve this market must follow strict documentation and quality standards.

The medical sector relies on precision machining for surgical instruments, diagnostic equipment, and implants. These parts need to be not only precise but also biocompatible and sterilised to meet health standards. Automotive manufacturers depend on custom machined parts for engines, transmissions, and electric vehicle systems.

Electronics and telecommunications also benefit from precision engineering for the production of housings, connectors, and components that support high-frequency applications. The demand for miniaturisation and performance drives innovation in this space, and London companies are increasingly aligning their services to support these needs.

How Much Does Precision Machining Typically Cost in London?

Costs can vary significantly based on the complexity of the part, the material used, and the volume required. As a general rule, simple CNC machined components will cost less than parts that require multi-axis machining, high-end materials, or secondary processing such as finishing or assembly.

The following table outlines typical pricing considerations:

| Factor | Impact on Cost |

| Part Complexity | Higher complexity increases programming and machining time |

| Material Type | Exotic alloys like titanium are more expensive to process |

| Quantity | Larger volumes reduce per-unit costs through efficiency |

| Tolerances | Tighter tolerances may require slower machining and inspections |

| Finishing Requirements | Polishing, anodising, or coating adds to the overall cost |

Basic parts might cost between £50–£150, while more advanced components could range from £250–£1,000+. Most companies provide bespoke quotations based on CAD files and specifications.

What Challenges Do Businesses Face When Outsourcing Machining Services?

Businesses often face several issues when working with new machining vendors. One common challenge is the mismatch between design expectations and manufacturability. If the initial design isn’t optimised for machining, it may lead to delays or cost overruns. That’s why some companies now offer Design for Manufacturing (DFM) support.

Another challenge is meeting delivery deadlines, especially for high-volume or complex parts. Delays in procurement or setup can cause a cascade of issues in the client’s supply chain. Quality issues are also common, particularly with newer or unverified vendors. Poorly machined parts may not meet the required specifications, leading to rework and additional expenses.

Choosing companies that have strong communication channels, dedicated project managers, and transparent processes can alleviate many of these concerns.

Is the Future of Precision Machining in London Driven by Innovation?

Innovation is reshaping precision machining in London and across the UK. The rise of smart manufacturing, also known as Industry 4.0, is encouraging companies to implement automation, data analytics, and machine learning to improve efficiency and reduce waste. Machines are increasingly connected to central monitoring systems that track performance, predict maintenance needs, and suggest efficiency improvements.

Sustainability is also playing a larger role. Modern machining centres are designed to reduce energy usage and minimise material waste. Companies are exploring ways to reuse scrap materials and adopt eco-friendly coolants and lubricants.

Hybrid manufacturing techniques such as combining subtractive machining with additive 3D printing are gaining ground in prototyping and specialised production. These methods enable more complex geometries and faster design iterations, creating new opportunities for product innovation.

Conclusion

Selecting a precision machining partner in London should begin with a clear understanding of your project’s technical requirements. Whether you need a short-run prototype or a full production line of complex parts, it’s crucial to evaluate companies based on their equipment, experience, certifications, and communication style.

Reviewing portfolios, speaking to past clients, and visiting facilities can offer deeper insight into a company’s capabilities. London has no shortage of experienced providers, but not all will suit your specific needs. A good partner will not only deliver accurate parts but will also offer guidance, flexibility, and support throughout the production cycle.

FAQs About Precision Machining Companies in London

What industries benefit most from precision machining services?

Precision machining is essential for aerospace, medical, automotive, telecommunications, and energy industries due to their demand for high accuracy and reliability.

Can I request both prototypes and mass production from the same company?

Yes, many companies in London offer both low-volume prototyping and high-volume manufacturing services, often supported by dedicated production lines.

How long does it take to get machined parts in London?

Turnaround times vary, but most projects range from 3–5 working days for simple parts to 3–4 weeks for more complex or high-volume jobs.

Are precision machining companies in London ISO-certified?

Many top firms are ISO 9001 certified, with some also holding AS9100 or ISO 13485 depending on the sectors they serve.

What is the difference between 3-axis and 5-axis machining?

3-axis machines operate on X, Y, and Z planes, while 5-axis machines add rotational movement, enabling more complex part geometries and fewer setups.

How do I choose between different machining materials?

Material choice depends on strength, corrosion resistance, weight, and cost. Machining experts can help recommend materials based on your end-use.

Do companies offer design assistance or just manufacturing?

Some precision machining companies also offer design support to ensure manufacturability and cost-efficiency, especially for new or complex parts.